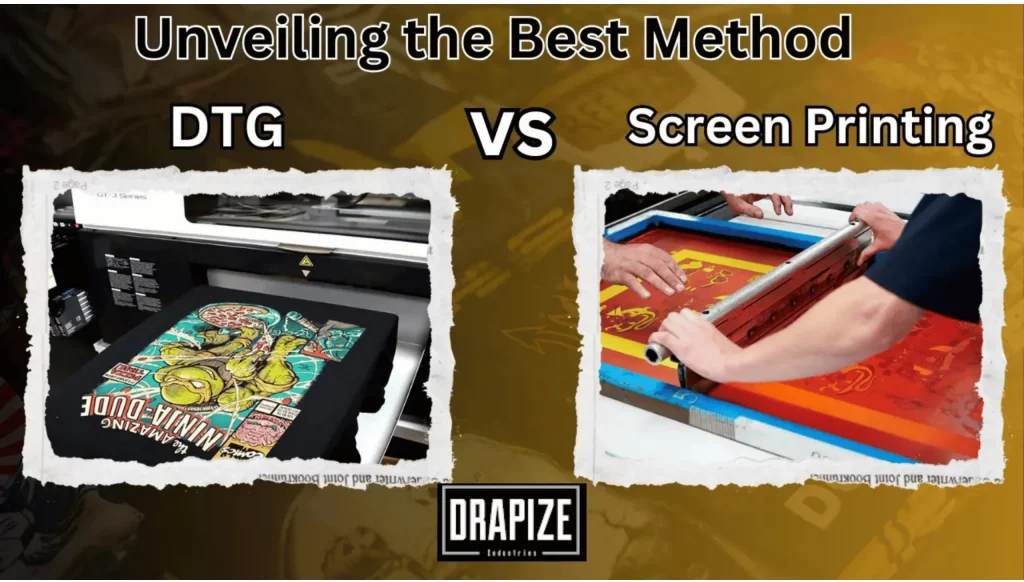

You’ve probably heard this from someone building their own t-shirt shop. Perhaps you have said it yourself. The excitement of envisioning a design concept can fade fast when confronted with more technical questions, the first of which is, Which apparel printing technology should I use?

There are several custom apparel printing options available, but the two most prevalent are direct-to-garment (DTG) printing and screen printing. Choosing the correct one for your online clothing brand might be the first step towards more delighted customers, lower costs, and the ability to grow your business as it grows. With so much at stake, it’s important to explore your alternatives and ask questions related to the two printing methods, such as:

- Will my design work with it?

- How cost-effective is it?

- How sustainable is it?

In this post, we’ll look at the differences between DTG and screen printing technologies, as well as the designs that perform well with both methods and how sustainable they are.

What is DTG printing?

Direct-to-garment printer (DTG) is a printing technology that involves pre-treating a garment with a bonding agent before jetting ink directly onto it. The ink then soaks into the garment’s fibres, where it is locked in by the link formed between the material and the ink during pre-treatment. The procedure is similar to printing on paper.

After printing, the garment is carefully removed from the printer and placed on a conveyor dryer to evaporate the pre-treatment and cure the ink, producing a long-lasting print that feels smooth to the touch. Because of its capacity to print photorealistic images and fine details, DTG printing is great for complex designs with gradients or a variety of colours.

The printing process is digital therefore, there is no need for considerable setup. When collaborating with a print-on-demand supplier, you can produce items with a modest initial expenditure because products are only printed when ordered.

What is screen printing?

Screen printing is a printing technique that includes putting ink through a mesh stencil and onto fabric. Each colour in the design requires its own screen therefore, multicoloured designs necessitate the use of many screens. Screen-printed t-shirts and other clothes have a thicker ink layer than DTG printing, giving them a more tactile feel.

Screen printing setup takes time because each colour needs its own screen. Once the screens are generated, the printing process is quick and efficient, making bulk orders less costly.

DTG vs. screen printing: Key differences explained.

When choosing between DTG and screen printing, important factors to consider include print quality, design complexity, and the ability to manufacture small or large volumes. Let’s see how the two ways compare.

Print quality and durability:

DTG prints provide exceptional clarity and detail, particularly in complicated designs with several colours or gradients. The ink adheres straight to the cloth, resulting in a silky feel and a long-lasting design that withstands multiple washings.

Screen-printed garments are known for their durability because of the thicker layers of ink used in the screen-printing process. These layers sit on top of the cloth, making the pattern extremely durable against wear, frequent washing, and abrasion. That is why screen printing processes are often utilised for workwear, uniforms, and other items that require long-term durability.

Print complexity:

DTG printing excels at handling complicated designs. opposed to screen printing, which requires a separate screen for each colour, a direct to garment printer prints the entire design at once, regardless of complexity. Design complexity also does not affect product pricing, making DTG printing excellent for firms that need to offer a diverse range of designs.

Screen printing is best suited for solid designs with few details. Explore basic typography, geometric designs, symbols, and shapes. This is due to the time required to create stencils for detailed designs, as well as the difficulty in getting the details correct during the printing process.

Since each colour is applied separately, screen printing is best suited for designs with few colours. Print providers frequently limit the number of colours you can use in your design, usually to a maximum of nine. In addition, the product pricing will be based on the number of colours in your design.

Colour vibrancy

Both DTG printing and screen printing produce vibrant colours, although they do so differently. During the screen printing process, ink is applied in thick layers, which can help designs stand out, especially on darker fabrics. This makes it particularly helpful for designs that employ only a few colours or rely on strong contrasts.

DTG printing provides outstanding colour vibrancy. The direct to garment printer technology provides for a wide colour range, and the inks are absorbed into the fabric, creating a smooth and natural finish. It works exceptionally well for lifelike or detailed photos while maintaining colour accuracy.

On-demand fulfilment

DTG printing is the obvious choice for on-demand fulfilment. About the fast setup time, businesses can print single items or small batches with low upfront costs. This makes DTG printing an ideal choice for an online store linked to a print-on-demand dropshipping provider such as Printful, where each item is printed only when ordered.

When a customer orders a single t-shirt from your store, Printful instantly accepts the order, prints your design on the t-shirt, and ships it directly to the client under your brand. This on-demand printing concept prevents you from having to manage inventories or handle shipping logistics yourself. You can still order in quantities if needed. Many print companies, like Printful, provide bulk discounts on DTG orders.

Screen printing, on the other hand, often has higher setup costs and minimum order requirements, making it better for big, one-time purchases over on-demand production. It is less flexible for businesses that do not wish to keep excess stock. Considering screen printing in bulk for your company or party? Let us know and get a quote in 48 hours.

DTG vs. screen printing: when to choose which?

Both strategies offer strengths based on the design you wish to create. Choosing the right printing process will save money, reduce waste, and improve turnaround times.

DTG printing is the best choice for designs with photorealistic graphics, detailed details, or a large colour palette. It’s also the best option if you want to print modest quantities or provide custom clothes on demand.

Screen printing is perfect for basic, bold patterns that rely on solid colours and lack complicated details. It’s the preferred option for large orders because expenses can be offset by longer manufacturing runs.

Choose your printing method wisely

Whether you use DTG or screen printing depends on what you’re selling, how much you create, and how adaptable you want your system to be. Before finalising a final decision, consider:

- The amount of detail and colors in your design

- Whether you want small print batches or bulk

- How much time and money you want to invest upfront

- Whether you want to hold inventory or use an on-demand model.

If you want to launch and grow with minimal risk, on-demand DTG printing is your best bet. With this printing method, it’s easy to introduce new designs to your store risk-free, and you don’t have to worry about keeping stock or shipping the items yourself. Using DTG print providers gives you more time to experiment with your product offering and marketing. It also helps eliminate overproduction, thus minimizing waste.

What’s your experience with DTG and screen printing? Let us know in the comments below!