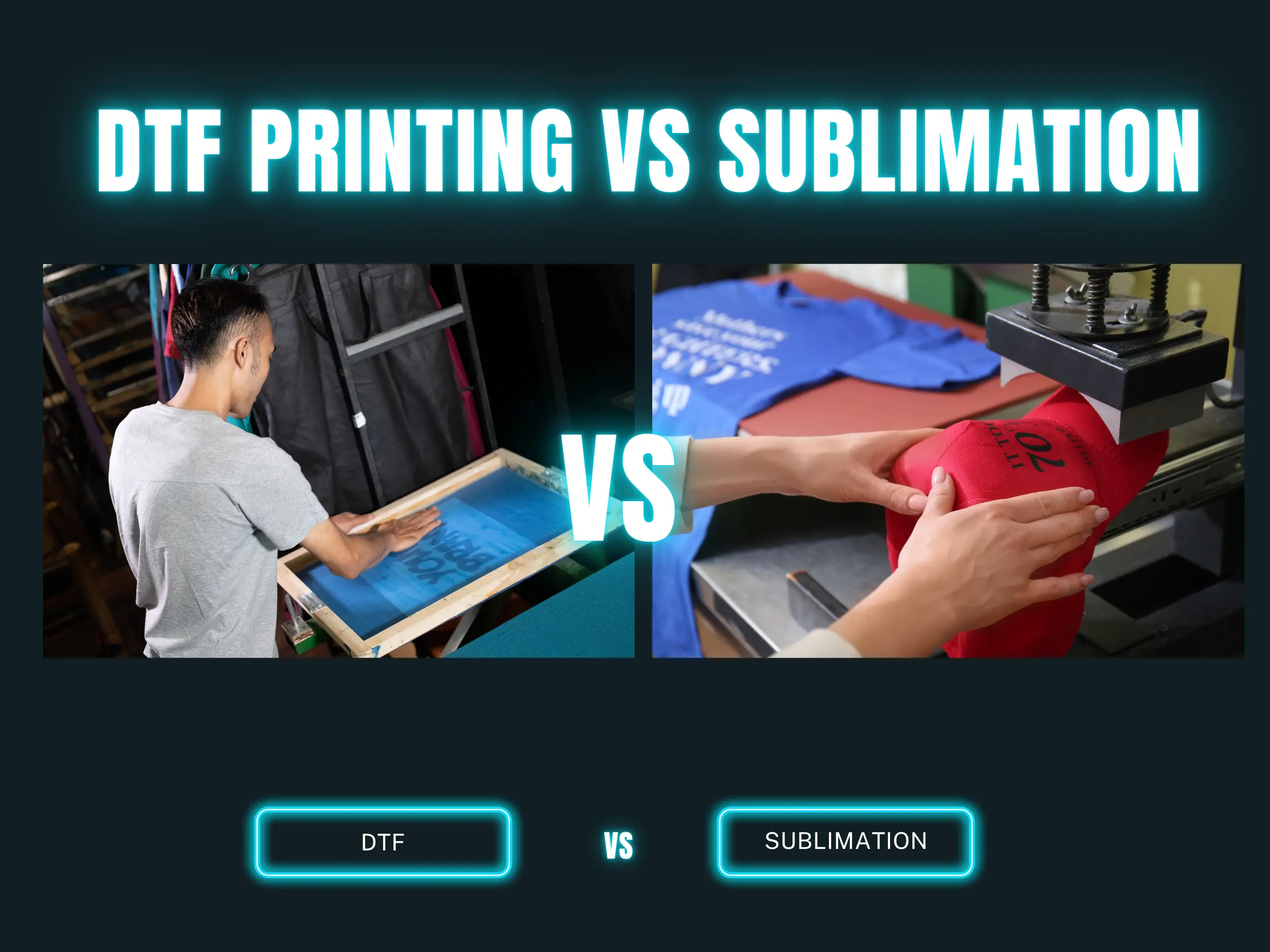

If you’re in the business of designing eye-catching designs for bespoke t-shirts, sweatshirts, or mugs, you’ve probably heard of Compare DTF printing vs sublimation to find the best method for t-shirts, mugs & more. Learn pros, cons, fabrics, and product suitability in 2025.. Both have gained popularity in recent years and offer excellent print quality.

In this blog post, we’ll compare DTF Printing vs sublimation printing methods, explain how each works, and discuss which products are best suited to each.

This book will help you understand the world of custom printing, from the technical tasks involved to the benefits and limitations of each method. Let’s get in!

What is DTF printing?

DTF printing, or direct-to-film printing, is a relatively new process that is gaining popularity because of its high quality and colour accuracy.

This digital printing method is known to generate long-lasting and colourful prints. This approach represents a technological improvement in digital printing, enabling a wider range of materials than the more commonly used direct-to-garment (DTG) printing.

How does DTF printing work?

The prints are created with advanced DTF printers that transfer colourful graphics straight onto film, which is then heat-pressed to the garment.

Here are the basics of the stages for DTF printing:

- The layout is produced on a unique transfer film using water-based inks.

- The ink on the film is then covered with adhesive powder.

- Next, the design is put onto the fabric using a heat press.

Although this process has several parts, t-shirt printing using a DTF printer is quick and just takes a few minutes.

What is sublimation printing?

Sublimation printing is a technique in which a design is embedded in a cloth or item using heat and sublimation ink. It’s a common print-on-demand technique to create all-over prints. The fabric is sublimated first, then cut and sewn together. The advantages include huge print areas, bright colours, crisp details, and long-lasting prints.

How does sublimation printing work?

Sublimation printing can be a lengthy procedure. This is how it works.

- The design is printed on special transfer paper with sublimation ink.

- The transfer paper is applied to the fabric and heat-pressed with a specific amount of pressure and time.

- The incredibly high heat converts the sublimation ink to gas.

- The sublimation inks bind with the cloth fibres, resulting in long-lasting prints.

DTF vs sublimation

Let’s go over each printing method in more detail so you can choose the best one for your printing business. Here’s a comparison between DTF vs sublimation in terms of print quality and fabric appropriateness.

Print quality and durability

DTF printing quality is fantastic. If you wish to print images, colourful designs, logos, or art, this is the method to use. The ink lies on top of the fabric, maintaining its detail and vibrancy during the printing process.

The prints come out smooth and elastic, ensuring durability. They can withstand heavy use and multiple washings without fading in colour. However, the design may develop tiny cracks if cleaned in actual hot water. Follow our care guidelines to ensure that the prints retain their colour and brilliance over time.

We do not recommend using the DTF method for printing large regions because it might make the garment feel heavy and stiff, reducing breathability.

Keep in mind that while DTF prints may appear stiff early on, they will relax after a few washings. Additionally, the print is thin, so it does not feel overly hefty. Sublimation printing, on the other hand, does not leave a raised print texture on the cloth and is therefore simpler to wear right away.

The sublimation printing quality is excellent. You can print detailed photographs in numerous colours that appear lively and sharp. The colour is incorporated into the cloth fibres, preventing it from fading or peeling, resulting in long-lasting patterns.

Print complexity

DTF prints are unparalleled in terms of print complexity. You may print intricate, full-colour designs, fine art, small text, and images. However, if you want to create a large design, DTF printing may not be the best option for you. DTF prints are not extremely breathable.

Therefore, printing a broad area makes the garment less comfortable for extended usage. The added weight makes the cloth feel heavy and stiff, and a large printed area often looks bad on the garment.

Sublimation printing allows you to generate detailed prints and designs of varying intricacy. It’s ideal for digital images, pattern designs, gradients, and brightly coloured artwork. Sublimation has a larger print area than DTF transfers, as it can cover the entire garment.

Sublimation printing bonds the printed image to the fabric rather than sitting on top of it, resulting in brilliant and long-lasting effects. Sublimation imparts dyes to fabrics, so finer details look sharp.

Color vibrancy

Both DTF and sublimation printing use the four fundamental colours (CMYK, or cyan, magenta, yellow, and black) for their prints. This means that the designs are manufactured in brilliant, vibrant colours.

Furthermore, both methods allow you to print gradients. However, keep in mind that the DTF print’s base (finishing colour layer) is white ink, which may have an impact on your design’s gradient or transparency. We normally do not recommend employing transparencies.

There is no white ink in sublimation printing, although the base colour limits can affect colour brilliance. For example, if you sublimate onto dark fabric, the colours will not be visible. Sublimation is typically applied to white or light-colored clothes. In contrast, DTF printing offers brilliant results on any cloth colour.

Fabric suitability

One of the main benefits of direct-to-film printing is the ability to print on a variety of fabric types. This includes polyester, cotton, fleece, nylon, and their fabric combinations. The print is not limited to a specific material, allowing for greater product customisation.

Sublimation printing works best on light-colored polyester, polyester blends, and polymer-coated fabrics. If you want your design printed on natural fibres such as cotton, silk, or leather, sublimation is not the best choice.

Sublimation dyes attach better to synthetic fibres, so 100% polyester is the best fabric option. The more polyester in the cloth, the more brilliant the prints.

Products

DTF technology and sublimation let you print on a wide range of products. Because DTF technology is a newcomer to the printing industry, you can use sublimation printing for a far wider selection of objects. Let’s have a look at the products we provide at Printful.

Apparel

Sublimation is the preferred t-shirt printing process for custom shirts with all-over prints. Drapize offers shirts in a variety of fits and styles, including sports jerseys, crew necks, tank tops, crop tees, and rash guards.

Sublimation is also excellent for sportswear, such as swimsuits and leggings, which can include bold prints and vibrant colours. You can choose from:

- Bikinis and swimsuits

- Sports bras

- Leggings

- Shorts

- And much more!

Although DTF print products are more limited, you can currently use the DTF method on several apparel items and accessories, like:

- 5 Panel Trucker Cap | Yupoong 6006

- Unisex Denim T-Shirt

- Lightweight Zip Up Windbreaker

- Recycled Tracksuit Jacket

- adidas Premium Polo Shirt

and more!

Home & living

Sublimation printing is a versatile process that allows for lots of creativity. It is commonly used to print home decor products like as blankets, bespoke mugs, cork-backed coasters, laptop sleeves, gaming mouse pads, and more. DTF printing is not presently available for any of the home interior goods, but keep tuned for future updates.

Quantity

If you’re looking for a printing technology that fits the print-on-demand concept, both DTF vs sublimation provide flexibility and ease. Both methods allow you to quickly print one item at a time or handle bigger bulk orders, making them adaptable to changing business needs.

There are no order minimums, so you may experiment with new designs or goods without having to worry about inventory. This increases creative freedom while lowering the financial risk of unsold stock, allowing you to test concepts and customise your products to client preferences.

Eco-friendliness

Both approaches allow for one-off printing, eliminating the need to worry about unsold stock and overproduction. If you’re seeking a sustainable fulfilment solution, DTF printing is a viable option. Direct-to-film printing uses water-based, non-toxic inks, which are considered more environmentally benign than standard printing technologies that employ solvent-based inks.

However, sublimation is a more environmentally friendly alternative to DTF printing. Sublimation uses dry inks that are infused into the material as it is printed. Unlike other dye transfer processes, the production process generates less waste and water. Furthermore, sublimation reduces waste ink by only applying it to the needed regions.

On-demand fulfillment

DTF vs sublimation are both good choices for on-demand fulfilment, making them suitable for print-on-demand companies. Both ways allow you to make one item at a time or fulfil large orders without the requirement for inventory. This enables you to offer unique products without making an initial stock investment, reducing financial risk and waste.

At Drapize, both dtf vs sublimation products are made only after an order is placed, guaranteeing that each item is tailored particularly to your customer. Whether you’re trying out new designs or scaling up for larger sales, the flexibility to easily transition between single-item and bulk fulfilment allows you to adapt to changing demands. Drapize also offers bulk order discounts, which can help you save money as your business expands.

Upfront investment

If you work with a print-on-demand (POD) provider to offer direct-to-film or all-over print items, you won’t need to make any upfront investments. That’s because your products are only produced when a buyer orders them. You collect money from your customers, pay for the product, and retain the profit.

If you want to print designs on your own, expect to invest a lot of money in printing equipment such as sublimation printers or direct-to-film printers. In addition, you’ll need to find blank items, specific inks, and arrange shipment. Because it requires an important initial dedication, dropshipping products with your designs through a POD supplier may be more cost-effective.

What is DTF printing best for?

If you offer things made of polyester, denim, fleece, or other heavy-duty textiles, DTF technology is a suitable fit. DTF printing allows you to make the most of different fabric types, print on both dark and light clothes, and avoid relying solely on polyester blends.

This approach is worth experimenting with if your designs are intricate and colourful. DTF prints feature great colour accuracy, and the results are vibrant, sharp, and long-lasting.

In addition, DTF printing is faster than sublimation, lowering production costs. Before deciding to sell products using DTF prints, test them out and order one for yourself. You might also compare the same design created using different ways.

What is sublimation printing best for?

Sublimation printing is an excellent choice if you’ve decided to dropship the products you sell because it’s one of the most common printing techniques offered.

Sublimation printing is the most suitable method for garment printing. It enables you to print detailed, vivid artwork, pictures, and patterns from seam to seam. If you want your graphics to totally cover a garment, sublimation printing is your best option.

This strategy is ideal for moving into the sale of accessories and home decor items. Sublimation printing is a popular technique for producing vibrant results on a variety of surfaces, including mugs, coasters, and blankets. Furthermore, it is an environmentally beneficial decision.

DTF vs sublimation: Which one will you choose?

In this post, you read about DTF vs sublimation methods, their benefits and drawbacks, and which items each method works best too.

If you still can’t decide which is best for you, try both! Don’t be afraid to try out each technique on different goods to find the one that works best for your ideas, whether it’s a hoodie with an all-over print DTF vs sublimation or a denim t-shirt with a detailed DTF print.

Have you used either of these printing methods? Tell us your experience in the comments!